72" x 30" a-frame dining table

72" x 30" a-frame dining table

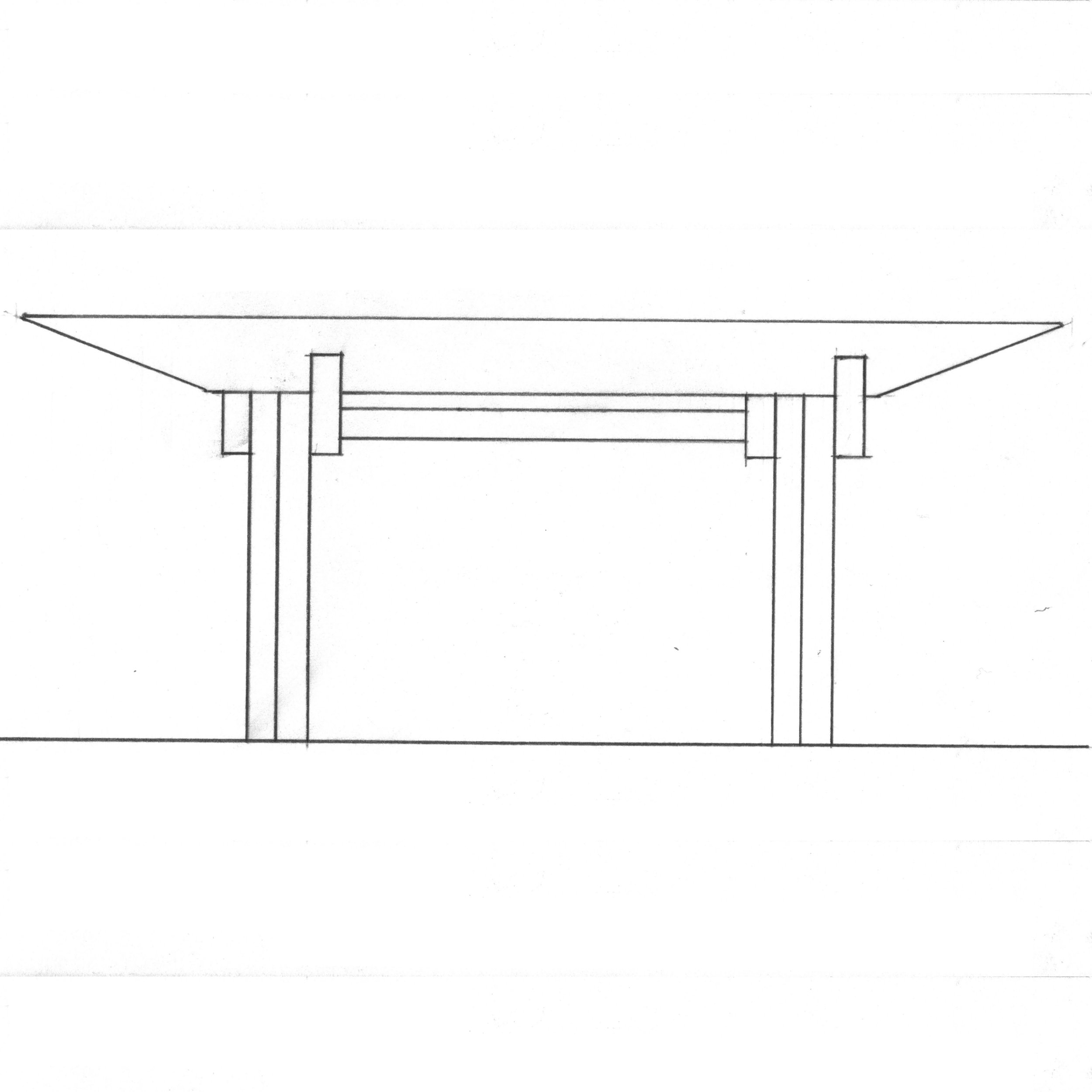

W 30 x L 72 x H 29

Inspired by a table on display at the Art Institute of Chicago by accomplished furniture designer Konstantin Grcic, called Table B. A tabletop made of extrusioned aluminum with open ends cut at 45º was conceived to work like airplane wings. Like the initial PetalPly system which took the language of steel by renown designer Jean Prouve and then re-imagined it for wood, this too followed the same exercise. Instead of working with long aluminum extrusions, the A Frame table top is made of long solid wood milled planks, thin skins of engineered panels, and patterned ribs to create an incredibly strong, light weight, hollow core structure that can achieve longer spans than most other tops.

PetalPly -

A frame sub-series

hollow core

A new direction has been taken, coupling an advanced version of earlier experiments in wood tectonics (see cubis cabinetry) with a base which is a variation on the Kid A sub-series. In short, the original experiment was to re-saw, edge glue, surface sand, and panel press solid wood using all yellow glue onto a stable wood veneer substrate, thus stabilizing the solid wood while allowing various sized and shaped panels. These tops use quarter inch solid wood pressed on one side of an equally thin substrate. The whole structure is wrapping torsion ribbing which is generously glued, and pressed to the engineered panels with a whole new technique, creating stunning triangulated objects.

low tech assembly

Normally some kind of caul and batten system with pneumatic or pipe clamps is used to press the panels together. Instead, measured out 1/8inch holes are predrilled, removable mini battens are custom cut and predrilled to correspond with the pre-drilled holes in the panels, which are corresponding with the inner torsion ribbing. Basically, these panels will be able to be pressed accurately and flat to a skeletal structure using nothing more than small pieces of scrap sized lumber, long screws with wide heads, and an electric drill. No need for larger space demanding cauls and battens, pipe clamps, and added bench space. Combine this with long milled solid wood edges and corners that are exactly shaped to allow for wide glue surfaces for the panels to be pressed onto. The result is a triangular top that can handle long and wide spans while being impossibly light thanks to its hollow core construction. The triangulated edges are elegant and aesthetically powerful.

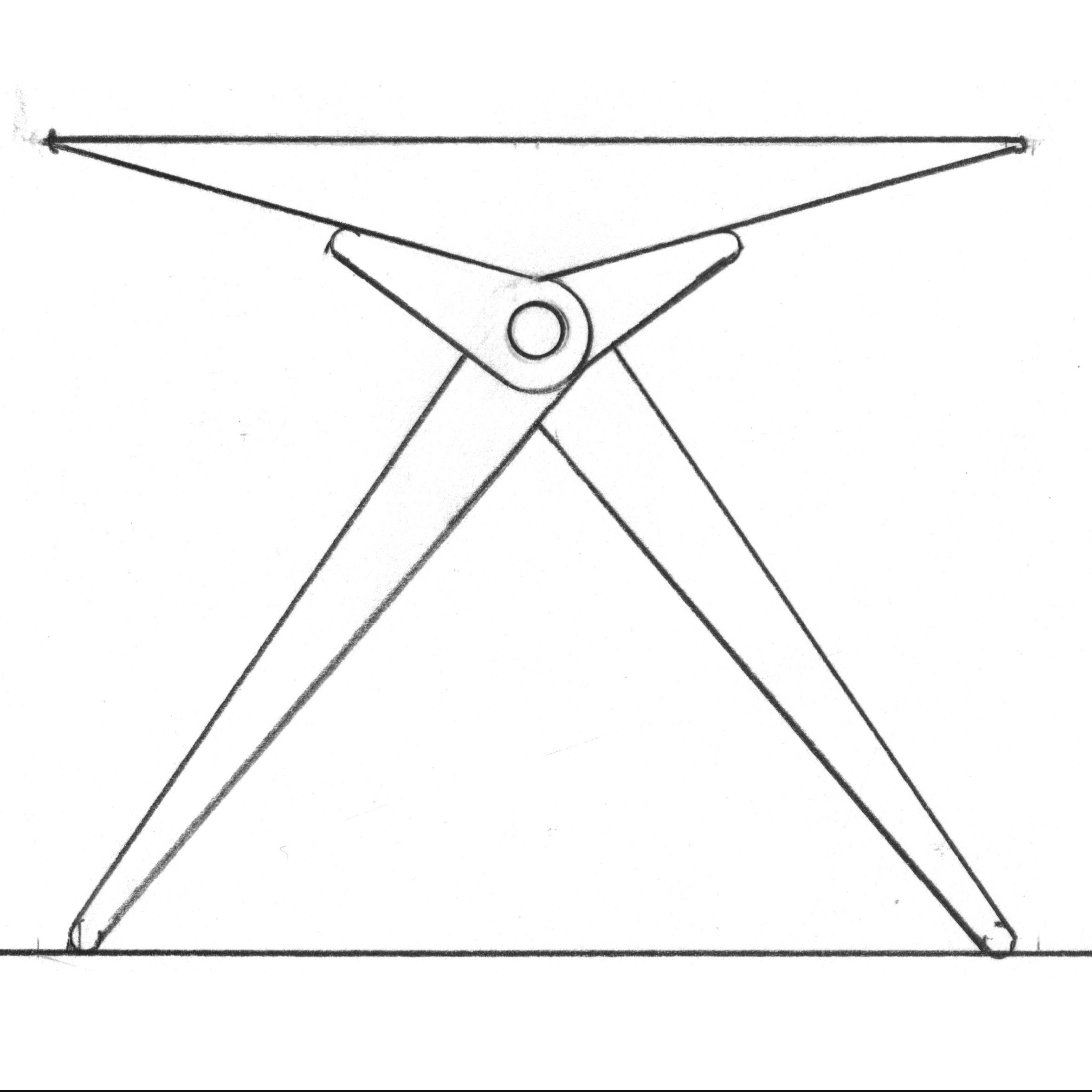

trestle bases

These triangulated forms saddle perfectly onto a unique take on the traditional trestle base, with a long spanning dowel that reduces wracking by mortising through four sets of double thick supports (petal legs and arms). Because of these double thick petals and legs, the dowel/stretcher is down sized from the two and a half inch dowel, used for the Kid A tables, to the two inch dowels found in the Sub-Series Two desks.